Carbon has the glamour, glass has the lion’s share

16 22

September 2027

Messegelaende HannoverGermany

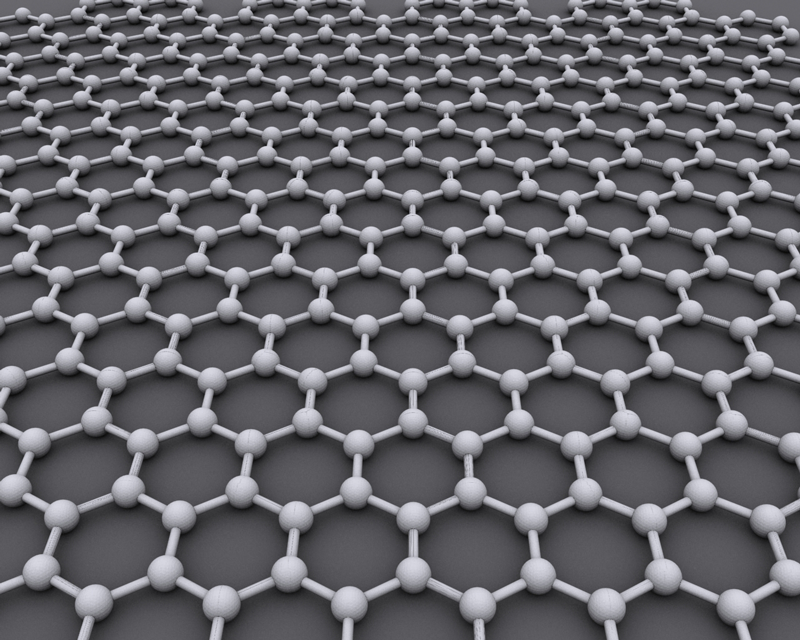

The extraordinary properties of graphene – among other things, it is the strongest material ever tested, efficiently conducts heat and electricity and is nearly transparent – led to predictions that it would become as ubiquitous as plastic following its discovery at University of Manchester in the UK back in 2004. Yet so far – while its potential continues to be explored by researchers globally – graphene’s commercial exploitation has been limited.

Graphene is the strongest material ever tested. (Photo credit: Alexander Alus)

A number of textile companies, however, believe that graphene has enormous potential to enhance the properties of fabrics.

One such company is Arvind, India’s leading textile-to-retail-and-brands conglomerate which produces over 100 million metres of fabrics and six million pairs of jeans each year.

G+ treatment

Arvind has just announced a collaboration with Italy’s Directa Plus, the developer of the G+ process for adding graphene to textiles.

The G+ treatment can be used to sustainably produce highly-performing fabrics that are independently certified as non-toxic, non-cytotoxic and hypoallergenic for human skin. Due to its patented process, Directa Plus is able to manufacture graphene-based products in sufficient quantities, at consistent quality – and at a commercial price point – to satisfy the textile market’s requirements.

Arvind produces over 100 million metres of fabrics and six million pairs of jeans each year. (Photo credit: A. Wilson)

The inclusion of G+ in textiles provides technologically-advanced fabrics with unique thermal features, allowing a homogeneous distribution of the heat produced by the human body in cold weather and a heat dispersion effect in hot weather. G+ also provides the fabrics with a bacteriostatic effect that enhances hygiene and anti-odour features.

Directa Plus reports that its sales of G+ fabrics during 2017 climbed to €770,000, from €80,000 in 2016.

The Italian sports brand Colmar launched an expanded collection of 16 garments incorporating G+ in 2017 and a new winter collection of 31 garments in 2018.

Another Italian brand, Eurojersey, has also launched a new Directa Plus G+ graphene textile collection this year under its Sensitive Fabrics brand. The warp-knitted technical fabrics are designed for high performance and targeted at the sportswear, athleisure and underwear sectors. Now Arvind will treat denim jeans with G+.

Eurojersey has launched a new Directa Plus G+ graphene textile collection under its Sensitive Fabrics brand. (Photo credit: Eurojersey)

Technology plays a vital yet invisible hand in determining the performance, fashion quotient and functionality of the denims we develop,” says Arvind CEO Aamir Akhtar. “The use of graphene in denims is absolutely new and will yield some of the smartest, most widely used fabrics in the years ahead. We are excited about the opportunities it presents, and we want our key customers to be amongst the first to experience and enjoy the advanced, new-age clothing we will create with Directa Plus.”

Investment in China

Meanwhile, UK company Versarien has earlier this year secured a deal with an as-yet unnamed global textiles and apparel manufacturer in China to focus on the incorporation of graphene into fabrics and a £55-million graphene manufacturing centre will is being planned.

Versarien’s Nanene graphene nano-platelets are so light and of such low density that a 0.5 g sample has a market value of around £200. To store a single ton of the graphene would require 38,000 conventional oil drums. Yet because such a small amount makes such a big difference, it is being manufactured to treat large volumes of materials at commercially-viable prices. Versarien’s graphene additives are incorporated into textiles via yarns and fabric finishes using an inkjet printing process.

“The accessible market for graphene is phenomenal,” says Versarien’s CEO Neill Ricketts, “because there is not a material that cannot be improved by it.”

Composites

While technical textiles are generally responsible for providing the reinforcement in composite structures, graphene is also being exploited in resins such as epoxies, as well as coatings, to add strength and other functional properties.

The UK’s Applied Graphene Materials, for example, has recently introduced an additive for an epoxy system developed with composites manufacturer SHD Composites and already employed in components for the automotive industry.

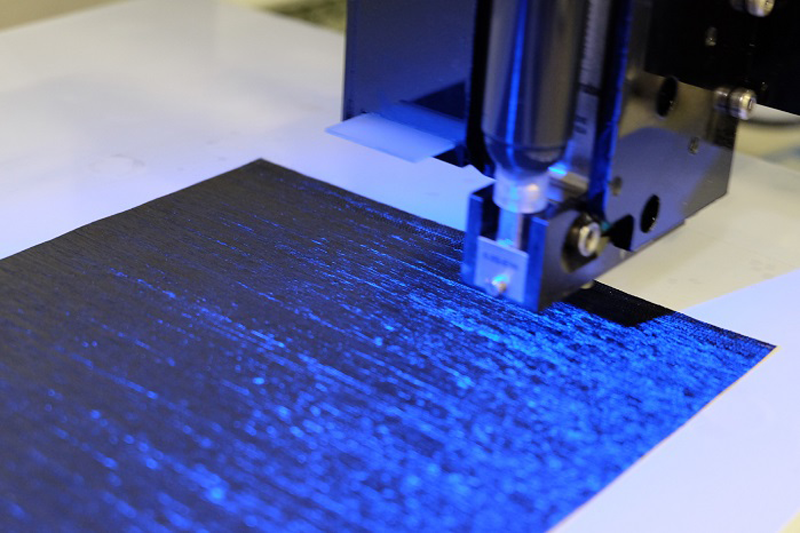

Structural Ink technology has been developed for the selective printing of graphene onto composite fabrics and structures. (Photo credit: Applied Graphene Materials)

The company’s patented Structural Ink is meanwhile a technology for the selective printing of graphene onto composite fabrics and structures. It is aimed at the optimisation of performance and reductions in both the weight of final parts and total manufacturing costs.

Subscribe to our mailing list and stay up-to-date with news and developments in ITMA and the textile and garment industry.