Carbon has the glamour, glass has the lion’s share

16 22

September 2027

Messegelaende HannoverGermany

ITMA 2019 exhibitors are increasingly moving into the field of technology for technical textiles, with a big market being the conversion of glass and carbon fibres into reinforcements for composites.

Textile companies have started to produce specifically for these markets and are now supplying a wide range of materials as the basis for high performance composites that are suitable for structural or semi-structural parts.

Such composites can incorporate fabrics, tapes or unidirectional prepregs, as well as long fibre nonwovens and mats, and the biggest opportunity for textile manufacturers within the field of mobility, including composites for aerospace, passenger cars and public transport.

Key trends in the mobility sector currently having a significant impact on the fibre and textile supply chain include addressing the issue of waste, in order to bring down the overall cost of carbon fibre composites, and above-average growth for thermoplastic-based technologies for the production of glass fibre composites.

The revival of sheet moulding compounding and compression moulding technologies is also opening up opportunities for the supply of nonwovens as core materials or surface enhancing layers, dry glass or carbon fibre fabrics and tapes as structural load reinforcement layers, prepregged fabrics or tapes and hybrid fabrics or nonwovens, such as combinations of glass and polyamide.

Research projects

Vandewiele, the Belgian-headquartered weaving machinery manufacturer, has been involved in a number of recent research projects to develop next generation textiles for composites.

It was a key technology partner, for example, in the €7.8 million 3D Lighttrans project that has led to the introduction of complex and cost-effective new 3D textile reinforcements for thermoplastic composites, including a tailgate for the Fiat 500L and a spare wheel well for Bentley

Central to the project was the Vandewiele VSi42 Versatile Smart Innovator weaving machine at TU Dresden’s Institute of Textile Machinery (ITM).

The double-rapier weaving loom and Vandewiele Jacquard employed in the production of bio-hybrid reinforcements at Hofzet. (Image: Hofzet)

Vandewiele jacquard technology is also proving central to research exploring the potential of hybrid woven technical textiles for composites at Hofzet, the Fraunhofer Institute for Wood Research.

The development of new and practical combinations of natural and high-performance fibres, such as flax, hemp and viscose, with carbon, glass or polyamide in multi-layer fabrics, is being carried out on a special double-rapier weaving loom and Vandewiele Jacquard attachment – the only one of its kind in Europe.

The weaving technology is enabling the Fraunhofer experts to cost-effectively produce materials with complex, application-specific textile structures and integrated functions.

New businesses

Meanwhile, Italian weaving machinery leader ITEMA is launching a new company to be called Itematech, dedicated to technology for technical fabrics. This follows the company’s acquisition of the know-how of PTMT (formerly Panter), a specialist in this field.

Autefa is also currently completing the installation of a fourth production line at its technical centre in Linz, Austria, dedicated to the production of nonwovens based on carbon and other advanced fibres for composites, as part of a €3.5 million investment. This follows successful developments with partners such as aerospace components specialist FACC.

Knitted preforms

A further new business is being established by Swiss knitting machinery manufacturer Steiger, which will introduce the new 3.130 compact knitting machine specifically designed for technical fabrics at ITMA 2019.

Steiger has recently been experiencing success in the field of knitted preforms for composites, and another project with the ITM at TU Dresden, for example, has successfully developed shaped truck component parts for Volvo.

3D knitted shells form the structure of the award-winning KnitCandela project. (Image by Philippe Block)

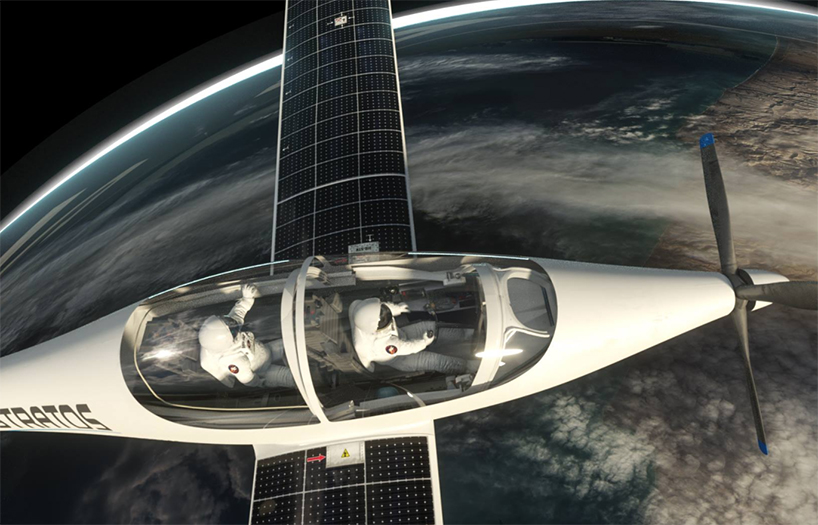

Two impressive projects within Switzerland have seen the development of the 3D-knitted shells to support a five-ton concrete structure as part of the award-winning KnitCandela project and Steiger has also been involved in the design of composites parts for the cockpit and seat covers of the Solar Stratos – the world’s first commercial two-seater solar plane. Following its success with these and other projects, Steiger is now opening a new business called Stitch Lab, dedicated to composite reinforcements.

Knitted composites are employed in the Solar Stratos - the world’s first commercial two-seater solar plane. (Image Solar Stratos)

Some ITMA exhibitors are now even specialising in the technology for composite reinforcements, such as Van Wees in The Netherlands, which has developed a complete programme for the turn-key delivery of production lines dedicated to the manufacture of technical textile reinforcements such as unidirectional (UD) and crossply materials, as well as textile lamination.

Expect to discover plenty of other composites-related innovations at ITMA 2019.

Subscribe to our mailing list and stay up-to-date with news and developments in ITMA and the textile and garment industry.