16 22

September 2027

Messegelaende HannoverGermany

For a number of decades now, the automotive industry’s supply chain has been highly structured and strictly managed top-down by the OEM vehicle manufacturers to ensure both maximised efficiency and just-in-time sequencing.

This extends not just to suppliers of components such as, as a textile example, automotive carpets, but also to the suppliers of the machinery on which these carpets are made. The machine manufacturers must be ISO 9001 certified and meet many other stipulations in areas such as power consumption and wastage.

Could this be the future for the highly complex and fragmented textile industry?

Sustainability goals

Having committed to ambitious sustainability goals by 2030, the majority of major apparel brands, as well as the corporations extensively using nonwovens and technical textiles in their products, are taking a greater interest than ever before in their supply chains.

They are now examining each link in the complex succession of processes that result in their final products, in order to more fully understand how they are being made and exactly what they are made from.

This new level of cooperation and transparency – stretching right back to the chemical and fibre producers – is to be welcomed, and can only lead to more sustainable practices across many areas, and not least in designing for circularity in the first place.

In examining the product components and process steps, however, one critical area can be overlooked – the role of the production machines themselves, and how they are operated on a day-to-day basis.

When nearly 80% of a machine’s environmental impact is decided during its design phase, it becomes the significant place for generating opportunities to develop more sustainable solutions.

However, the ecological goal of ensuring products that are easy to repair, maintain and decommission often conflicts with the economic imperative to drive down manufacturing costs and drive-up productivity.

Optimisation

The ability to optimise material selection, energy consumption, emissions and waste by-products based on environmental impact, in addition to cost and performance, is crucial for today’s manufacturers.

Recovery flows such as materials and by-products that are identified as waste or undesirable should inspire designers and product development managers to repurpose them as inputs. It is these upstream decisions made by designers that can massively affect sustainable solutions during a machine’s lifecycle, and the material recovery and recyclability at the end of a product’s life.

I foresee the circular economy for textile machinery being significantly influenced by better and disruptive design. Circular design should concentrate not only on improved recovery infrastructures, energy efficiency and recuperation, new recycling technologies and materials reuse, but also on the questions of what the product should be, how it works, and how it satisfies customer needs in more efficient and effective ways. Ultimately, the businesses which can successfully move towards a circular economic model will be more efficient, profitable and investable.

It is vital for all participants at next year’s ITMA in Milan to now consider designing their machines for decommissioning and support customers to achieve maximum efficiency throughout the operational lifetime of each machine.

Further, machine builders need to be actively involved in the supply chain conversations that are now being instigated by the brands and corporations who in the end, have the ear of the consumer.

Jason Kent, CEO, British Textile Machinery Association (BTMA)

About BTMA

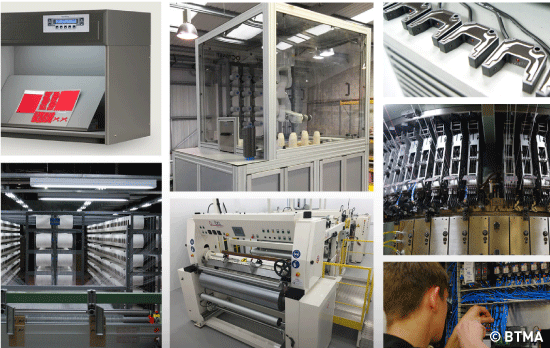

Established in 1940, the BTMA represents 45 UK companies with expert services in all aspects of the technology for textile manufacturing.

Subscribe to our mailing list and stay up-to-date with news and developments in ITMA and the textile and garment industry.