16 22

September 2027

Messegelaende HannoverGermany

What are intelligent textiles?

Here’s an example – imagine being able to change the colour of a room simply by scrolling around the colour spectrum on an app with your finger. What about then eliminating the app altogether, and being able to change the colour of the walls in the room by a simple machine-learned hand gesture?

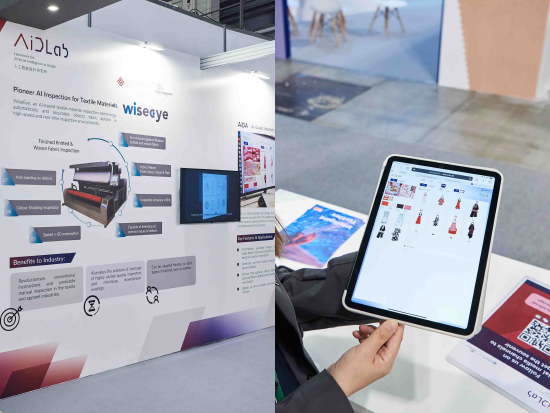

This is what the Hong Kong-based AIDLab is working to commercialise and it could have huge implications – not only in fashion and interior design, but also in therapeutic environments, since colour has been proven to significantly impact human moods and wellbeing.

AIDLab focuses on the integration of artificial intelligence (AI) with design, and was jointly established by the Hong Kong Polytechnic University (PolyU) and the UK’s Royal College of Art in London, with the aim of transferring advanced research ideas into new commercial products.

“Utilising computer vision and illuminating optical fibres, these new intelligent fabrics are designed to recognise hand and body gestures to customise colours instantly,” explained AIDLab centre director Professor Calvin Wong here in Milan yesterday. “The patented design and technology transform conventionally passive fabrics into interactive textiles, enabling the dynamic customisation of both the fabrics and entire environments.”

In other projects, AiDA is an AI-based interactive design assistant for fashion, empowering fashion designers to significantly simplify their original designs and bringing agility, efficiency and flexibility to conventional processes.

“It’s all about treasuring human creativity and enabling fashion designers to speed up the realisation of their designs,” said Professor Wong. “Those who we’ve worked with it have told us that 60 to 70% of the time a project normally takes can be saved with AIDLAb.”

AIDLAb's latest AI-powered innovation.

In a more immediate example of advanced data in action, the UK’s Shelton Vision has developed a unique new fabric inspection technique for accurately detecting defects on patterned fabrics during high speed production.

“What our new system basically does is make the ‘good’ pattern on the patterned fabric invisible to the detection software,” explained Shelton Vision CEO Mark Shelton. “Building on our market leading vision system for plain textiles, we have developed template-matching techniques for the resolution of complex pattern deformations in order for the system to pick up defects in the pattern, as well as underlying defects.

“The challenge is that fabrics are not rigid and can be creased or stretched and are also subject to local distortion. As a result, inspection without the technique we have developed, would lead to thousands of false positives. Our pattern inspection software techniques ensure a clean image, allowing the detection of faults on fabrics running at speeds of up to a hundred metres a minute.”

The patent-pending system has been integrated into Shelton’s WebSpector platform – a powerful plain fabric inspection system on the market – and validated through factory trials on a purpose-built full scale in-house demonstration system.

Traditional methods for defect detection rely on human inspection which can be ineffective, with detection rates under 65%. The Shelton WebSpector offers a sophisticated platform for automated defect detection of over 97%, but until now has been restricted to plain textiles.

Shelton Vision CEO Mark Shelton.

Swiss-headquartered Stäubli is a long established leader in weaving technologies, with a portfolio spanning cam motions, dobbies and jacquards and drawing-in, leasing and warp-tying machines.

Its latest developments draw on the company’s wide experience in robotics and digitalisation, which global head of marketing Fritz Legler explained are intertwined with process efficiency.

“The better you control the process the more sustainable you are,” he said. “We are constantly developing new and improved high-performance solutions for processing fabrics for fashion, home fabrics, carpeting, automotive, protection and medical applications, as well as highly complex technical textiles for future applications. Our technologies are based on more than 2,200 granted or pending patents and are already used on approaching 70,000 weaving machines worldwide.”

An example of advanced digitalisation in action is to be found in the company’s PRO series of jacquard machines, which were launched at the end of 2022 for enhanced energy efficiency in the production of flat, terry, or one-piece woven fabrics.

They are available in formats ranging from 4,608 to 25,600 hooks – with each individual position controlled by the company’s latest Noemi electronics architecture, enabling perfectly synchchronised hook lifting during high speed weaving for each single yarn.

Stäubli’s latest developments draw on the company’s wide experience in robotics and digitalisation.

This is digitalisation very much in action here at ITMA 2023 in Milan!

Subscribe to our mailing list and stay up-to-date with news and developments in ITMA and the textile and garment industry.