16 22

September 2027

Messegelaende HannoverGermany

In the textile industry, it is critical for producers to maintain a proper level of humidity as it improves the efficiency of the process and ensures the best quality of the finished product. Controlled humidity also eliminates the risk of static electricity build-up, which makes the processing of the material more difficult.

The right level of humidity also helps reduce the amount of dust in the air and improves the quality of the environment where products are manufactured or stored. In factories, textile machinery could also develop a lot of waste heat, causing the ambient temperature to rise.

As such, high-performance textile mills have great demands on room climate and process air. Air engineering plays a vital role in controlling these conditions and providing the necessary climate for machines and processes. Efficient air engineering is paramount for economical production.

Digital control technology

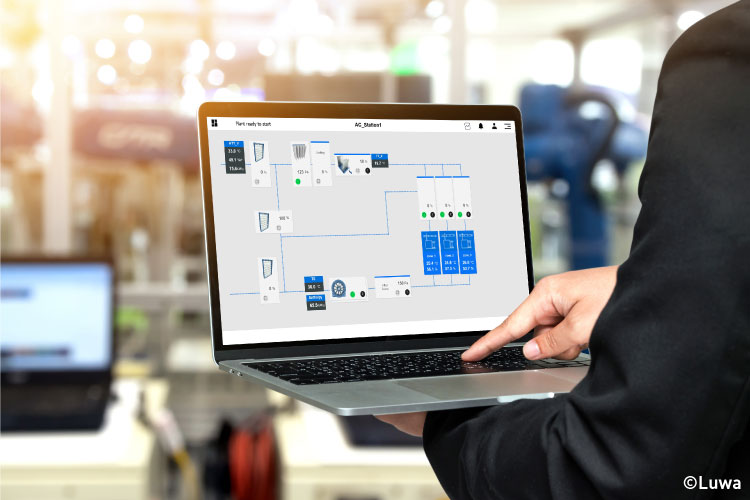

Renowned for its quality and performance in the control of textile air conditioning and filtration, Luwa has produced a combination of hardware, software and cloud services to move industrial environments to a new level.

Increasing plant efficiency, productivity and safety at the same time requires an integrated approach to product design, system configuration and digital control. Close synergy between the production equipment and the climate control system also needs to be maintained. Luwa sees the industry from a holistic, best performance perspective. It is possible to control processes at low cost but the total costs of ownership need to stay in line. Superior quality and attention to detail guarantees this.

Digital process control is not new. The clear difference in products like Luwa’s is the focus on implementation of years of real applications knowledge into the operating software. In addition, the structure of the control components assures easy monitoring, fault isolation and remedy if needed so that energy is saved and output is maximised.

DigiControl 7 is capable of precisely controlling industrial environments with minimal human intervention. Luwa’s augmented its capabilities when it joined the Nederman Group. In an industry-leading investment, Nederman introduced a cloud-based dashboard, “Insight” that allows visualisation of sensor data and equipment status in real-time from anywhere in the world.

But data in itself is not the answer to uptime and productivity challenges. With Luwa-Assist, our air engineering experts regularly check performance measures, give status updates. Client-defined notifications and visualization of performance trends support proactive maintenance efforts.

Luwa is part of the Nederman Group´s commitment to be “the Clean Air Company”. Our facilities are working toward carbon neutral solutions and have introduced energy-reducing technology to our plants. The most obvious contribution to our customers sustainability objectives is the total Luwa climate control system. Energy reduction is delivered by closer control of the environment and improved output of textiles per energy unit used. Finally, human resources are better protected and can find solutions to problems faster with less travel and fewer process steps.

Ulf Mattisson, CEO of Luwa states, “Our strength is to harmonise equipment, control and applications knowledge. DigiControl 7 builds on that strength with top-class controls technology and IoT solutions.”

Alan Traylor, Vice President, Global IoT and Marketing, Luwa Air Engineering

About Luwa

Founded in Switzerland in 1935, Luwa is a global market leader in textile air engineering and a quality and performance leader with a global brand in the fibre and textile industry. The Luwa Group’s activities include the design and engineering of single components and whole systems as well as manufacturing, assembly, installation and after sales services. The Group has subsidiaries in more than 60 countries.

Subscribe to our mailing list and stay up-to-date with news and developments in ITMA and the textile and garment industry.