The roadmaps to tomorrow's garment industry

16 22

September 2027

Messegelaende HannoverGermany

In the competitive, resilient and innovative textiles sector that is envisaged in the European Commission’s Strategy for Sustainable and Circular Textiles, published on 30 March this year, textile manufacturers will have to take responsibility for their products all along the value chain, including when they become waste.

Here in Sweden, entirely new industries are already being established in response. We are seeing newly-formed businesses developing sustainable cellulosic fibres from waste clothing, based on the legacy of the country’s pulp and paper industry and drawing on its know-how to de-risk and get to scale quicker.

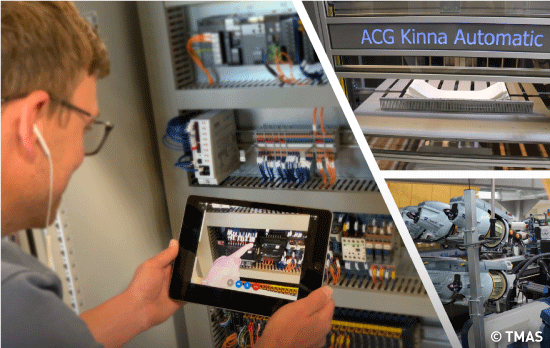

New textile recycling infrastructure is also being put in place, including the world’s first fully automated sensor-based textile sorting plant which has just opened and has the capacity to process up to 18 tons per hour of post-consumer textile waste.

Sorting textiles according to the various types of fibres they contain requires a high degree of precision and when done manually, doesn’t meet the requirements of the recycling or fashion industries. The new automated sensor-based sorting system in Sweden has proved efficient in separating different textile fractions by both material type and colour.

Between the creation of new fibres and the end-of-life of garments, however, sits the entire textile chain, including member companies of TMAS and their customers, the textile manufacturers.

In welcoming the EC’s strategy – and the promised support that will accompany it – TMAS member companies intend to do all they can to help their customers transition to what is required with all the advanced tools at their disposal.

Many of the environmental benefits implicit in regenerated fibres, for example, can be vastly diminished when they are subjected to conventional textile processes such as dyeing and finishing. Here, TMAS companies including Baldwin, Coloreel and Imogo have developed new, digital technologies which can vastly reduce the use of the fresh water, wastewater, energy and chemicals that has been required to date.

Digitalisation and the push for more sustainable, shorter and less expensive supply chains is meanwhile leading to a trend for more localised and automated textile manufacturing by making production in high-cost countries within Europe more attractive.

The Covid-19 pandemic exposed the vulnerability of many countries to shortages of essential items, while at the same time making the full exploitation of new digital options essential during national lock-downs and long periods of restricted travel. The escalating cost of global transportation, as well as the growth of online retailing and the associated benefits of on-demand digital manufacturing, are further reinforcing the many benefits of short-run and near-shore new operations.

The automated technologies of TMAS member companies including ACG Kinna, Automatex, Eltex, Eton Systems, Vandewiele Sweden (formerly Iro AB), Svegea and Texo are helping producers in many fields to reduce repetitive manual tasks and increase efficiency, which evens out some of the differences between production in high and low-cost countries, making reshoring a feasible option.

ACG Kinna, for example, has recently acquired Nowo, a provider of fibre processing technologies, in order to further integrate and extend the automatic lines it supplies. Automatex is meanwhile providing automatic bag-making machines to weaving companies who themselves are expanding integrated production. There is much more that is being currently addressed by TMAS members, notably in the fields of transparency and the calculation of carbon footprint to further assist its customers.

Specific measures of the EC’s new textiles strategy include eco-design requirements, clearer information and a proposed Digital Product Passport, all of which will only be enabled by new technology developments.

Rest assured, TMAS members are working hard to future-proof your textile business.

Therese Premler-Andersson, Secretary General, Textile Machinery Association of Sweden (TMAS)

About Textile Machinery Association of Sweden (TMAS)

TMAS is made up of leading Swedish companies within textile technology, automation and production processes. The expertise of its members ranges from advanced systems for yarn fault detection and tension monitoring, to yarn feeding technology for weaving, automated sewing production lines, cutting machines, embroidery technology, material handling systems, spray application system for fabric finishing, and much more.

Subscribe to our mailing list and stay up-to-date with news and developments in ITMA and the textile and garment industry.