Crucial roles for carbon composites

16 22

September 2027

Messegelaende HannoverGermany

The VDMA marks 125 years of progress

Germany’s Mechanical Engineering Industry Association, the VDMA, has now been actively promoting knowledge on the benefits of mechanical engineering for 125 years, and with the advent of Industry 4.0, now has bigger messages to convey than perhaps at any time in its history.

To mark this year’s 125th anniversary, the VDMA has put together a series of multimedia reports on a new website – https://humans-machines-progress.com – in which the major topics facing the world today, including work, energy, health, urbanisation and materials, are examined.

“Since the beginning of time, humans have longed to take their future into their own hands,” says Thomas Waldmann, managing director of the VDMA Textile Machinery Association, “and since then, humans have been designing, building and using machines for this purpose. Humans, machines and progress are thus intrinsically linked. Humans use machines to improve the lives of all on this planet, but what are the biggest challenges facing mankind and what contribution are machines and mechanical engineers already making today to solve them?"

“Throughout the year, we will publish more reports on the major challenges of our time. What will work look like in the future and what roles will robots play in it? How will energy be used tomorrow? These are a few of the questions we will seek to address.

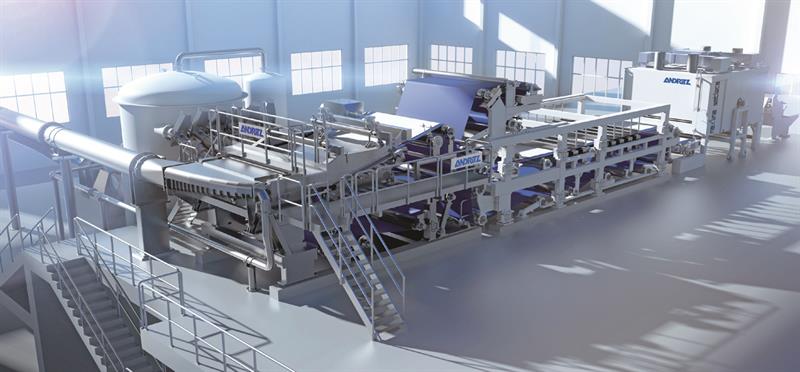

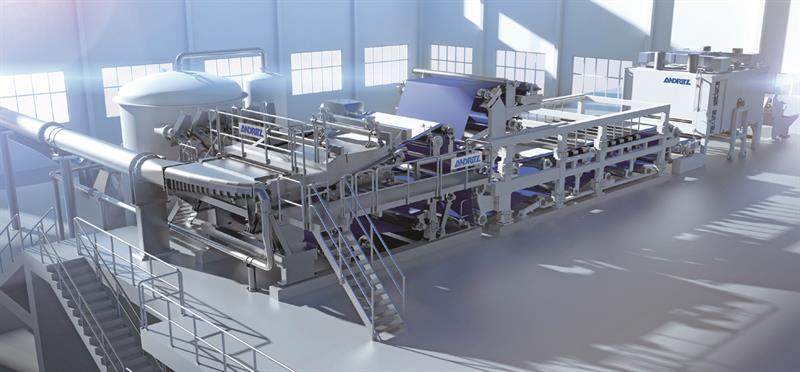

Andritz Nonwoven’s wetlace technology, which combines wet forming and hydroentanglement, is suited for the production of quality flushable wipes

Future health

The textiles manufactured on modern machinery have a major role to play in meeting many new challenges.

In fighting disease, for example, advanced textiles impregnated with insect-repellents are used in regions where malaria poses a risk and protective clothing is vital in the fight against all arising contagious epidemics.

The use of textile-based implants such as stents, heart valve replacements and artificial cartilage or tissue is also growing strongly in modern surgical techniques and materials are also getting smarter.

“Intelligent textiles can now heat up, be luminescent, generate energy and communicate,” says Waldmann. “Garments with integrated sensors are already commercially available, including shirts that can measure pulse, breathing and body movement, heated underwear, heated jackets with communication and lighting systems. There are even inlay soles with GPS tracking devices or smart shoes that can be opened up, closed or heated up using an app, while also counting steps and calculating calorie consumption. Smart textiles are already very useful in the medical field, whether for the preventive monitoring of breathing and heart rate or for keeping track of wound healing processes.

Thomas Waldmann, Managing Director, VDMA Textile Machinery Association

Energy savings

As reinforcements for composites, textiles perhaps have big role to play in meeting the demand for more efficient transport, infrastructure and energy.

Enormous savings potential in aerospace has triggered major developments in lightweight construction, where along with aluminium and titanium, fibre-reinforced plastics are the fastest-growing lightweight construction materials, based on knitted, woven or nonwovens fabrics.

An increasing proportion of carbon fibre reinforced plastic (CFRP) is incorporated in wide-bodied aircraft and these composites also now play an important role in automotive construction. In its development of the i3 and i8 electric and hybrid vehicles, for example, BMW has used CFRP and developed a passenger compartment in series production for the first time. Mechanical and plant engineering companies played a significant role in the process development and automation of the production steps.

“The boundaries of what is feasible have been continuously pushed and important lessons have been learned for the future use of fibre composites,” says Waldmann.

Better buildings

Carbon fibre-reinforced concrete, recently developed in Germany, will be another important material in maintaining buildings, bridges and towers going forward.

“Infrastructure maintenance is currently time consuming and costly because the reinforced concrete that has been used in many structures contains steel reinforcing bar that can corrode, making the concrete structure crack,” explains VDMA publicity officer Nicholai Strauch. “Textiles offer a robust alternative by replacing the steel with carbon. Carbon concrete is durable, environmentally friendly and versatile in its uses. The carbon used to reinforce concrete is even stronger than steel, but at the same time much lighter and more durable since it does not corrode. Building elements made of carbon concrete can thus be thinner, reducing demand for raw materials and as a result, energy use and CO2 emissions are cut almost by half.

Leading flat knitting machine manufacturer, Stoll presented an innovative software tool for networking of large machinery plants at ITMA 2015

Rapid changes

Work, of course, is changing too, as a result of digitisation and Industry 4.0, and both textile machinery builders and their fabric manufacturing customers can expect a rapidly-changing environment in the next decade or so.

Robotics are increasingly replacing hard, repetitive and unhealthy manual labour, but more than ever, we will need human expertise in respect of both production and customer requirements,” says Strauch. “History has shown that every revolution in production and every new level of automation has ultimately created more new and higher-value jobs.

In modern production sites, workers also need professional and protective clothing to protect them from injury and safeguard against hazardous environments. Air conditioning is meanwhile becoming widespread in the modern working world – even in regions with no weather extremes. Air and dust filters made of nonwovens are already playing an essential role in protecting workers, as well as sensitive equipment, in production plants.

Around 120 of the most important manufacturers of textile machinery and accessories from all sectors of the trade are affiliated within the VDMA Textile Machinery Association and exhibit regularly at ITMA shows. Collectively, they are responsible for annual sales of around €3.4 million, the lion’s share of which is achieved via exports.

Subscribe to our mailing list and stay up-to-date with news and developments in ITMA and the textile and garment industry.