Relationships are everything

16 22

September 2027

Messegelaende HannoverGermany

The R&I (Research and Innovation) Pavilion at ITMA 2019 – one of the four key components of the show’s Innovation Lab – will provide an opportunity to connect and exchange ideas with a truly international gathering of expert researchers and academics who are involved in a vast range of textile-related projects.

In addition to the many major textile institutions from across Europe, organisations will also be present from North and South America, Asia and Australia. Adding to the vibrancy of the area will be a number of first-time participants, such as Fundació Eurecat, Leitat Technological Centre, Manchester Metropolitan University, Mittelstand 4.0-Kompetenzzentrum Textil Vernetzt, Thomas Jefferson University and Universidad De Buenos Aires’ Fadu, Cátedra Nirino Diseño Textil.

Within Europe, some key research trends in individual countries are notable, even as the European Union’s comprehensive research programmes strive towards encouraging co-operative projects across borders.

Composites potential

In both France and Germany, for example, there is a strong emphasis on the further development of textile technologies for the composites industry, backed by major end-user organisations such as Airbus, as well as car brands such as BMW, Daimler, Peugeot-Citroen, Renault and Volkswagen.

Reinforcements for composites involve a wide range of the technologies which will be displayed at ITMA 2019, including weaving and knitting, as well as nonwovens manufacturing, embroidery and braiding.

More than 20 university institutes focus on state-of-the-art production techniques at RWTH Aachen University in Germany.

One nerve centre for developments in this area is RWTH Aachen University, where more than 20 university institutes focus on state-of-the-art production techniques and are cooperating with machinery makers, robotics companies and software developers to make manufacturing processes efficient enough to allow high-wage countries such as France and Germany to compete on a global level.

Microfactories and maths

Automation and Industry 4.0 are also key focus areas in Europe, and Germany’s Institutes of Textile and Fibre Research Denkendorf (DITF), for example, has recently been involved in the multi-company co-ordination of digital textile microfactories. These have involved fully automated and interlinked textile production lines for ‘make on demand’ products – from design through to the finished and printed garment.

More than 20 university institutes focus on state-of-the-art production techniques at RWTH Aachen University in Germany.

One nerve centre for developments in this area is RWTH Aachen University, where more than 20 university institutes focus on state-of-the-art production techniques and are cooperating with machinery makers, robotics companies and software developers to make manufacturing processes efficient enough to allow high-wage countries such as France and Germany to compete on a global level.

Microfactories and maths

Automation and Industry 4.0 are also key focus areas in Europe, and Germany’s Institutes of Textile and Fibre Research Denkendorf (DITF), for example, has recently been involved in the multi-company co-ordination of digital textile microfactories. These have involved fully automated and interlinked textile production lines for ‘make on demand’ products – from design through to the finished and printed garment.

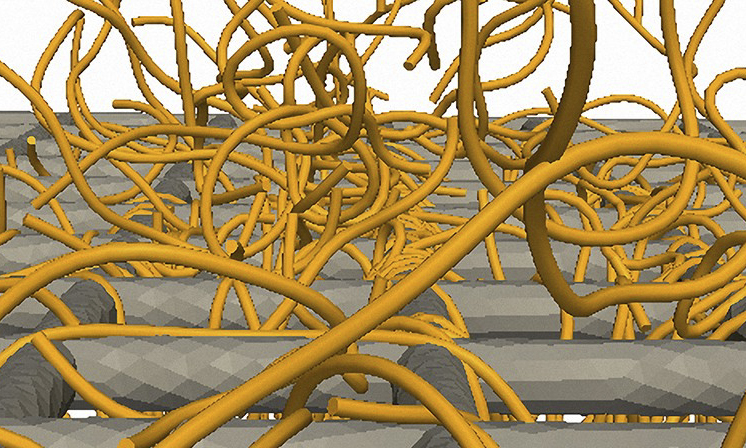

The Fibre Dynamics Simulation Tool (FIDYST) makes it possible to simulate the movement of fibres in turbulent air currents for the first time.

Another intriguing development from a German research institute is the Fibre Dynamics Simulation Tool (FIDYST) which makes it possible to simulate the movement of fibres in turbulent air currents for the first time. This was developed at the Fraunhofer Institute for Industrial Mathematics, another R&I Pavilion participant, and will have a very positive effect on the process planning of nonwovens manufacturers.

More than a century ago, French mathematicians Eugène and François Cosserat worked on equations to describe the behaviour of elastic materials. The theory of Cosserat-Rods, named after them, ultimately formed the basis for this new development by the Fraunhofer researchers.

Science of the small

The Czech Republic can rightfully claim the title of the world’s leader in the development of nanofibres and the technology for producing them.

The Czech Republic can rightfully claim the title of the world’s leader in the development of nanofibres and the technology for producing them, with almost 30 separate companies now involved, and the majority having emerged from the Technical University of Liberec.

From their origins as filters for Russian gas masks back in World War 2, electrospun nanofibres came to be widely explored in laboratories around the world as their full potential was realised with the advent of the scanning tunnelling microscope at the start of the 1980s. The drive to perfect the high speed, industrial manufacturing of nanofibres for textile applications, however, remains ongoing, and most notably in the Czech Republic.

In the performance apparel market, for example, materials that offer different levels of breathability and water resistivity are being perfected. They can be engineered with the required porous structure from a range of polymers. For air filtration, meanwhile, nanofibres provide the high specific surface area and small, interconnected pore structure which allows a very low basis weight coating to achieve high filtration efficiencies while maintaining a low pressure drop.

ITMA Innovation Video Showcase

A new platform introduced to further highlight innovations at ITMA is a showcase of videos which features the contributions of ITMA 2019 exhibitors selected by a panel of industry experts.

Christine Karin Schmidt, chair of the CEMATEX working group of the ITMA Innovation Lab, and Technical Director of VDMA Textile Machinery Association, explains: “There is much more to be discovered at the ITMA Innovation Lab. The Innovation Video Showcase will spotlight the most groundbreaking exhibits at ITMA 2019.

“By presenting these latest innovations in a video format at the Speakers Platform, CEMATEX aims to further promote excellence in R&D and make the Innovation Lab a hotspot that will inspire visitors from all sectors of the textile and apparel making industry.”

Subscribe to our mailing list and stay up-to-date with news and developments in ITMA and the textile and garment industry.