Early adopter brands see the benefits of digital developments

16 22

September 2027

Messegelaende HannoverGermany

Photo caption: Workflow technology connects directly from design to the finished, packaged product. © ESMA

All of the pieces are in place for the rapid growth of digital textile printing in the next 20 years.

It is being predicted that from just a 7% share of the overall textile printing market in 2021, digital printing will climb to a 25% share in 2030 and to 40% in 2040. The final barriers and bottlenecks to acceptance are being overcome by advances in both the technology and the inks, as well as major changes in the supply and demand of the market.

There is no doubt that the textile industry is currently in a state of flux, with environmental, economic and technical pressures driving the industry towards new models, both in respect of how products are manufactured and how they are sold.

Digital printing ticks all the boxes as a big part of the solution.

One big driver for its growth is the fact that it is now widely recognised that fast fashion as it exists today is simply not sustainable.

Since the mid-1990s the relative price of clothing in Europe has fallen by over a third and at the same time, collections now change many times per year, resulting in lower quality, throwaway items that are worn less than ten times. While the price for cotton has remained largely unchanged for 50 years, retail margins have increased from 30% in 1970 to 70% in 2020. Value has not been fairly distributed among contributors, as brands have continuously sourced from countries with lower wages.

Historically, the focus on cost has encouraged mass production and low-priced garments. Production is distributed around the globe with raw materials shipped in and finished products shipped out. Consequently, CO2 emissions can be more than ten times the weight of the end product due to a convoluted supply chain.

Huge volume production has also led to overstocking at retail, but this is no longer acceptable. Production runs are shrinking, in part due to the rise of online shopping and make-to-order production, but also because the high-end brands – who in the past have not allowed their unsold stocks to be discounted, choosing instead to destroy them – can no longer afford the damage to their reputations or the costs of such wasteful procedures.

The textile industry‘s today complex supply chain makes effecting change within it difficult, but in addition to allowing the reduction of the number of steps in the actual manufacturing process, digital printing can also accelerate the adoption of much shorter and more streamlined work flows in automated processes.

Significant savings in time and resources can be made just by replacing conventional rotary (screen) printing systems with new digital technologies.

To screen print a design involves the expensive and time-consuming preparation of screens for each separate colour, making the cost for short runs extremely high. The size of a design is limited to the circumference of the cylinder and PFP (prepared for print) treatments are required. This traditional process route lacks the flexibility demanded by today’s market.

With digital printing there is no limit to the size of the designs and many colours can be printed simultaneously. Many individual designs can also be printed together in a single operation. There is no requirement for ink blending, toning, initial printing and drying steps, prior to the final printing process, as is the case with plates, and no cleaning requirement afterwards.

This eliminates a great deal of waste in inks, water and energy.

In rotary six-colour printing, around 50-60 litres of water are consumed per linear metre in various process steps. This compares to 14-20 litres per linear metre in digital production – a reduction of two-thirds or more. It has been estimated that the replacement of all rotary systems with digital alternatives would result in annual savings of some 760 billion litres of water.

In energy, the same replacement would save around 800 million cubic metres of natural gas per year – the monthly consumption of Belgium’s population – and 1,000 GWh of electricity.

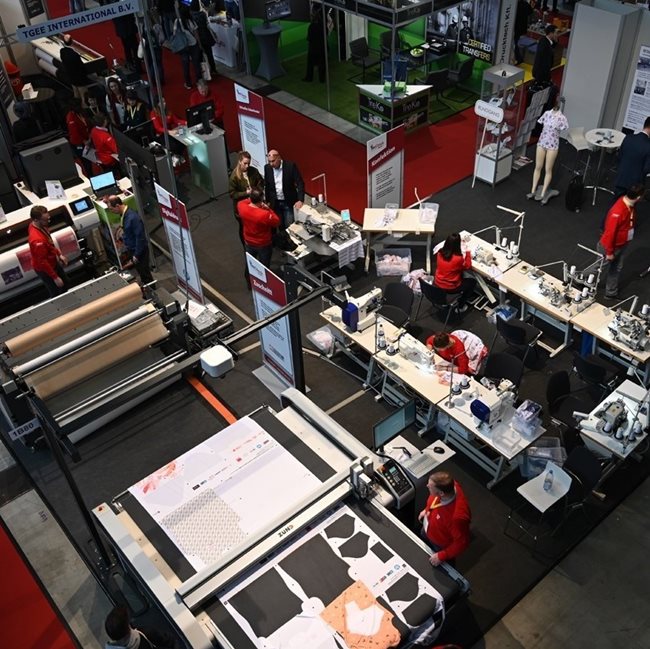

Photo caption: Digital printing is central to the rise of microfactories. © ESMA

We are now seeing the rise of microfactories in Europe, to which digital printing is central and workflow technology connects directly from the order to the final invoice, and from the start of production to the finished, packaged product.

These microfactories are bringing companies closer to the buyer and allowing them to produce only what is needed, or even better, to produce on demand.

This model eliminates waste and significantly reduces the carbon footprint of manufacturing operations, as well as transportation and logistics.

Being closer to customers, of course, is exactly what brands want to achieve, and there is a further opportunity to involve consumers via personalisation (and optional extras) that can be offered for uniquely-produced garments.

We are now very much in a transition from analog to digital as the engine for a more sustainable and circular textile industry.

Peter Buttiens, CEO of ESMA

About ESMA

ESMA is a leading, non-profit, association in Europe for specialist printing manufacturers of screen, digital and flexo technology. It was founded in 1990 as the European Association of Screen Printing Equipment Manufacturers. Today, ESMA’s focus is on all industrial, functional and specialised printing applications, as well as graphic applications that lead to disruptive developments in printed interior decoration, printed electronics, plastics (IMD and FIM), textiles and glass.

Subscribe to our mailing list and stay up-to-date with news and developments in ITMA and the textile and garment industry.