Working with customers closely on tailor-made solutions

16 22

September 2027

Messegelaende HannoverGermany

At the last ITMA exhibition in Milan four years ago, the major advances in digitally-printed textile processing were evident. Implications were quickly realised all along the textile manufacturing chain, with digital printing central to concepts of new ‘just-in-time’ operations closer to their intended markets, or ‘micro-factories’ made possible by software-powered automation solutions. A move from mass manufacturing to short batches and customisation in many areas is now happening.

Pictured this afternoon at the European Digital Textile Conference (left to right) are Carlos Lahoz, HP’s global textile brands strategist, Lewis Shuler of Under Armour Print and Material Innovation and Bart Sights, technical innovation senior director at Levi’s.

In 2016 the global volume of digitally-printed fabric was put at just under 1.2 billion square metres by WTiN, which held the European Digital Textile Conference alongside ITMA here in Barcelona today. Following the many innovations introduced at ITMA 2015, this had climbed to 2.57 billion square metres by 2018 and there are already more than 43,000 digital printers said to be in operation.

At this ITMA so far, the sales have been coming thick and fast. MS Printing Solutions, for example, has already announced the sale of ten machines, including three of its MS Mini Lario systems and three LaRio models to customers in Bangladesh, Italy, Spain and Turkey.

MS Printing Solutions has announced the sale of ten machines at ITMA 2019.

And SPGPrints has announced the sale of a Javelin multi-pass printer to Polish company Teofilów, as well as a bestLEN 7412 direct laser engraving machine to Mexican knitted fabric company Windsor. Durst has meanwhile secured contracts for delivery of its Alpha 330 machines to customers in Brazil and Pakistan.

Amazon backing

Kornit sold their on-demand textile production system to Amazon.

Kornit has also announced new sales here in Barcelona, extending its list of very high-profile customers, one of the most notable being Amazon.

Amazon has not only purchased a large number of Kornit on-demand textile production systems, but at the beginning of 2017 launched a scheme to purchase around US$38 million of the company’s shares over a five-year period, such is its belief in this technology.

Following the success of its Storm HD6 and Avalanche HD6/HDK machines, Kornit has this year launched the Atlas direct-to-garment printing platform. The heavy-duty system has been created for super-industrial garment decoration businesses and is designed to deliver a typical annual production capacity of up to 350,000 impressions. As such, it is aimed at highly productive garment decorators, mid-to-large size screen printers and businesses looking to combine state-of-the art technology with lowest cost of ownership.

The system is equipped with both new recirculating print heads and a newly-developed ink, NeoPigment Eco-Rapid.

The Atlas printing engine is complemented by a professional RIP (raster image processing) software solution, and produces prints to meet the highest standards of retail quality and durability. It comes ready for Kornit’s planned future release of its cloud-based business intelligence, productivity analytics and optimisation software platforms, scheduled to be released in the second half of 2019 in time for ITMA 2019.

Hybrid

Mimaki is showing a brand-new hybrid digital textile printer, uniquely featuring both direct-to-textile and direct-to-transfer print capabilities. These features enable textile and garment manufacturers to achieve unparalleled flexibility and also allow multiple sets of inks to be loaded simultaneously, supporting increased fabric range versatility and maximum product variety.

Mimaki is also demonstrating its TA Job Controller software, specifically designed for textile production environments, for use on the company’s Tiger Pro and Rimslow TR printers enabling users to connect one-on-one to the RIP (raster image processing) and other devices, for an automated workflow from design to pre-print, print and post-print processes.

Sustainable processing

Performance art at EFI Reggiani in Hall 3.

As I reported in my last blog, EFI Reggiani has already sold a number of its new Bolt machines, but the company has also been doing a lot of work on sustainable processing. Its Terra process for pigment prints, for example, completely eliminates the need for steaming, washing and stentering, cutting the process down to just preparation and printing together with inline polymerisation. Similarly, the company’s latest Direct Sublimation process for the transfer printing of polyester and polyester/elastane fabrics has eliminated steaming and washing as a result of inline fixation. Again, not only do these new processes result in tremendous savings, but also shorten the process times.

Brands perspective

In a special closing session organised by HP at today’s European Digital Textile Conference, Lewis Shuler of Under Armour and Bart Sights of Levi’s spoke of the digital transition being made by the two brands.

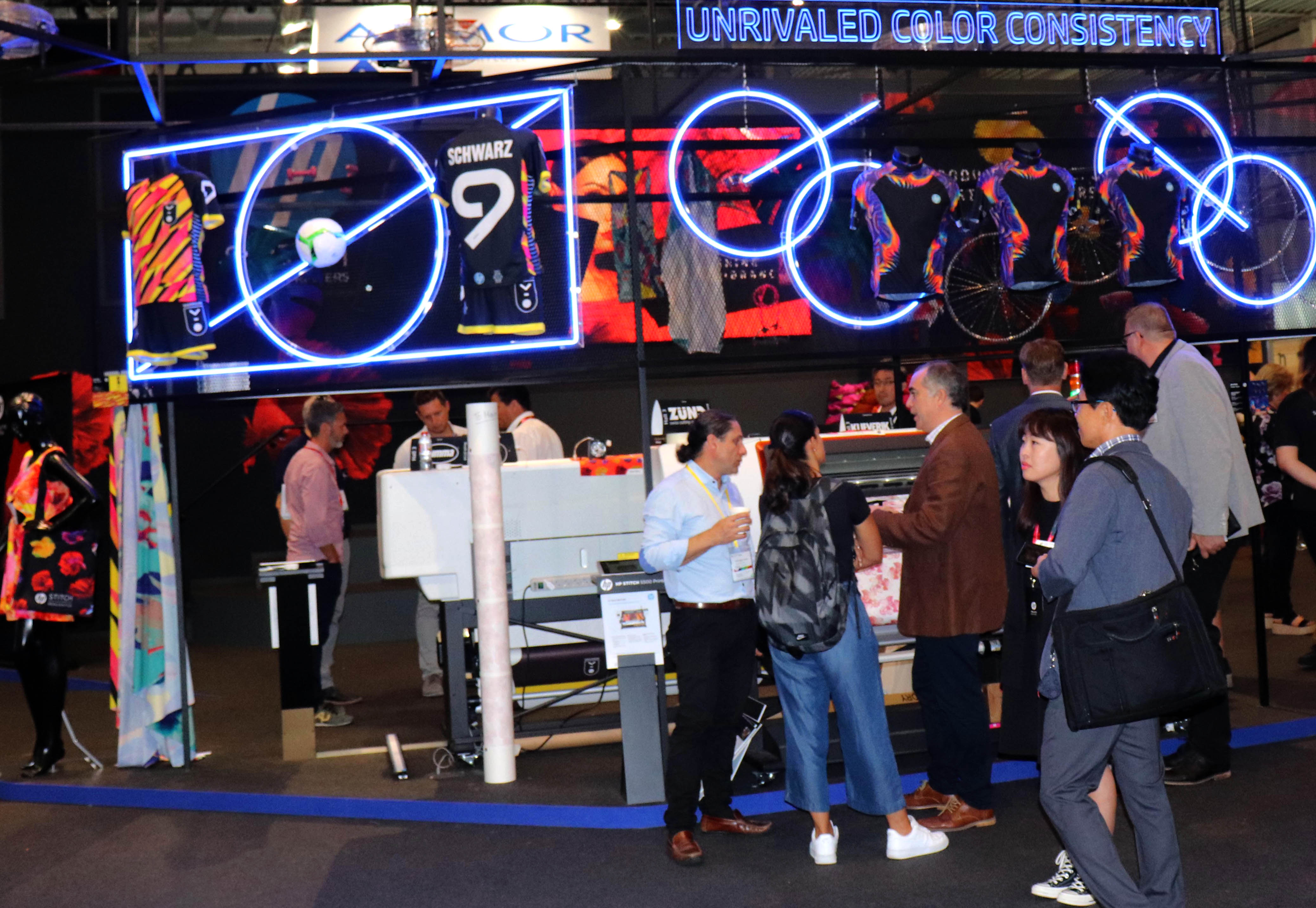

HP’s stand in Hall 3.

The benefits of such a move were outlined by Carlos Lahoz, HP’s global textile brands strategist. “Last year H&M had to announce it had a US$4.3 billion inventory of unsold clothes and obviously digital seems to be the solution to such problems,” he said. “It also promises targeted and on-demand garment production, locally and sustainably.

For the past two years Under Armour has been pursuing its Digital First strategy which has seen the performance wear brand grow its digital sublimation from 5% to 90% of its inventory with plans to next move to direct-to-fabric digital production.

Our brand is very agile which is a big advantage,” Shuler said. “The key reasons for the transition, along with the many sustainable advantages, was to cut down and be able to better manage inventories and lead times, get rid of repeat issues and improve photo-real colour options. Our reasoning was the quicker we jumped on it the more it would help us in the long term, but while we have very good partners, it still took some persuading both internally and externally.

Levi’s is not digitally printing its denim jeans but through its FLX programme is digitally finishing them with laser treatments. “FLX happened initially when we wanted to eliminate a certain chemical,” Sights said. “We then realised that if we were to pivot this back to the design stage we would have a lot more flexibility.

Levi’s jeans are now produced by suppliers in standard light, medium and dark shades and shipped to the brand’s own distribution centres, where their final design and finishing is carried out in response to market needs. The brand is planning to launch the Levi.Com website later this summer which will allow consumers to personalise the finish of their own denims.

“In-store will follow in the future,” Sights said.

Subscribe to our mailing list and stay up-to-date with news and developments in ITMA and the textile and garment industry.