A new benchmark for dyes and chemicals

16 22

September 2027

Messegelaende HannoverGermany

Customisation is the key to international success for AMEC AMTEX, Spain’s textile machinery organisation. The organisation consists of some 40 manufacturers who achieved €343 million in sales in 2016, with €310 million of this being export sales.

Like the textile machinery branch of Germany’s VDMA, AMTEX gains considerable leverage from being a part of the larger Amec organisation, which brings together Spanish manufacturers of machinery and equipment across all industrial sectors.

AMEC companies contributed over €8.5 billion to the country’s economy in 2016, while providing direct employment to more than 38,500 people.

As part of AMEC, we promote business through a range of services and activities aimed at strengthening the internationalisation of our companies,” says AMTEX Director Carmina Castellà, who has just returned to Barcelona from trade missions in Iran and Colombia on behalf of the organisation’s member companies. “Organising networking events is very important as there are clear benefits in sharing experiences which often generate synergies.

Carmina Castellà, AMTEX Director

Of equal importance, are the important technical centres and universities situated mainly in Catalonia and Valencia, where much of Spain’s textile industry is centred and with whom AMEC AMTEX companies have strong co-operations which the organisation strives to reinforce.

The major markets in 2016 for Spanish textile machinery were Mexico, Portugal, India the USA and France, followed by Bangladesh, Italy, Turkey, Pakistan and Bangladesh. This list can change from year to year, however, since major projects in specific countries can significantly alter the rankings.

Specialisation

For Ms Castellà, the specialisation of the majority of Spain’s textile machinery manufacturers is a key strength.

“It’s about working with specific customers on tailor-made solutions, building close relationships with companies and their owners wherever they are in the world,” she says. “If somebody asks for 40 standard machines, many of our companies might not be in a position to supply them, but generally the ability to supply specific solutions for individual companies is the key to success.”

One of the largest of the AMEC AMTEX companies, for example, is Catalonia-headquartered Electro-Jet, which has pioneered the automation of yarn spinning systems over the last 35 years and today has a leading international position in the supply of travelling cleaners for these installations.

Valencia-based Jeanologia, meanwhile, has done much to advance the science of denim finishing and carved itself market leadership in the supply of systems for environmentally-friendly laser and ozone treatments for fabrics. Currently, over 20 per cent of the five billion pairs of denim jeans manufactured each year are finished with Jeanologia technology.

Jeanologia paves the way for more environmentally-friendly denim finishing solutions

Companies such as Galan, Icomatex, Motocono and Twistechnology are meanwhile all based in the historical Catalonian textile centre of Terrassa, and well established in the supply of twisting systems, finishing machinery and modular winding.

Still growing

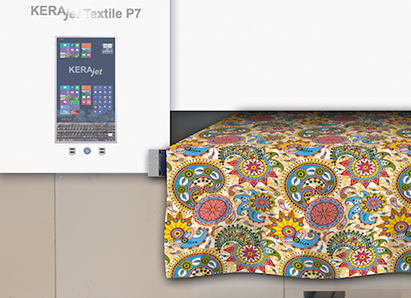

AMEC AMTEX also continues to grow, with one of its latest new members being KERAjet, based in Almazora, a company which has long been established in the ceramics industry and has now adapted its advanced digital printing technology for the textile industry.

From ceramic digital decoration to textile printing, KERAjet pushes the boundaries of efficiency in print production

This is a good example of the synergies that can result from being part of the broader AMEC network,” says Ms Castellà. “We are very pleased to be attracting new members, of course, and it shows the industry continues to develop. At the next ITMA here in Barcelona, Industry 4.0 is likely to be a major theme because everything has to become easier in terms of the connections between machines and mills, with the growing use of electronics and robotics.

The environmental impact of production chains also has to be considered, in addition to the optimisation of the use of energy, water and raw materials. These will continue to be that major topics for textile machinery manufacturers, in addition to increasingly adapting technologies for the production of technical textiles and nonwovens.

She added, “We are very much looking forward to welcoming everyone to Barcelona again in 2019, after the highly successful show here in 2011.

Subscribe to our mailing list and stay up-to-date with news and developments in ITMA and the textile and garment industry.