Over-production is a major concern for the denim industry and in one response to it, Candiani Denim has opened a microfactory in the heart of Milan where clients can buy completely customisable men’s bespoke jeans.

Italy’s FKgroup collaborated with Candiani on the development of the light and quiet Biliardo Sample cutting machine which is installed at the microfactory and characterised by its flexibility and low consumption for sustainable, zero-waste production.

Candiani received the ITMA 2023 Sustainable Innovation Award in recognition of the development of its microfactory and has also recently developed and patented Coreva – billed as the world’s first 100% biodegradable and compostable stretch denim fabric thanks to the engineering of a natural, eco-compatible elastomer which doesn’t release microplastics once thrown away.

FKgroup’s commercially-available Super Jeans automatic conveyor cutting system has been specially designed for denim and is capable of accelerating working cycles in terms of both speed and productivity. Its cutting head has been specifically designed for cutting high lays of denim.

New raw materials are naturally part of denim’s sustainable differentiation agenda and hemp, for example, has been widely employed in jeans by leading brands including Tommy Hilfiger, Lee, Levi’s and Timberland.

Hemp-Act, based in Lacapelle-Marival, France, is an expert in the cultivation and production of this natural fibre and supplies technology transfer, bespoke decorticating lines, project support and knowledge transfer for new businesses looking to enter the rapidly growing market.

“We can supply agile and flexible technology for the extraction of long fibres and the use of its co-products – short fibres and hemp shives – calibrated to local industry no matter what size, and with an at-hand international network of industrialists to provide technological monitoring and advices,” says founder Pierre Amadieu.

Hemp, he adds, is an easy plant to grow in many latitudes and economical in both its use of water and resources. At ITMA 2023, Hemp-Act had many fruitful discussions with spinners primarily from Turkey, Pakistan, India and Bangladesh.

An essential process during denim fabric production is sanforizing, which prevents shrinkage and is carried out on special finishing machines manufactured by ITMA exhibitors including Brückner, Monforts, Morrison Textile Machinery, Sperotto Rimar and Yamuna.

During sanforizing, the warp threads of the fabric are shortened and the weft threads compressed within very specific parameters, before the fabric is stabilised by tension-free drying.

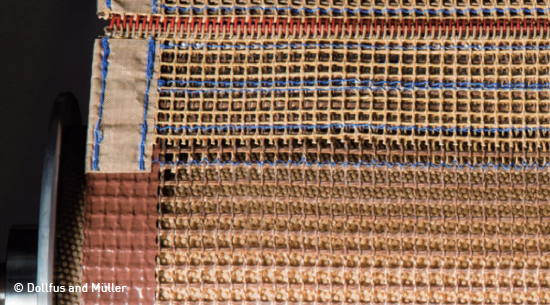

The technical textile belts transporting the denim fabric during this essential process are specially manufactured by Dollfus and Müller from high-strength aramid fibres. The French company has specialised in a wide range of transportation belts and technical felts for the textile industry for over 200 years.

The post-treatment of denim jeans is meanwhile an area that has traditionally used a lot of water and this is an issue which is being successfully addressed by Spain’s Jeanologia, most recently with its Atmos system, for achieving vintage-look denims without water, chemicals or pumice stones – just air.

Using G2 ozone technology and the patented Indra system which achieves perfect control of the humidity and atmosphere temperature, the Jeanologia Atmos can attain the same effects that were previously only possible with water and chemicals, or pumice stones, while ensuring perfect reproducibility and enhanced productivity in a more efficient, sustainable and safe way.

Click here to view more exhibitors and products on ITMAconnect.

Includes ITMAconnect account with access

until 14 November 2026.

Purchase an ITMAconnect visitor ticket at EUR 25 (VAT at prevailing rate to be added if applicable) to access the platform until 14 November 2026.

Subscribe to our mailing list and stay up-to-date with news and developments in ITMA and the textile and garment industry.

Share this page

Stay Updated on Industry Developments

Featuring products and exhibitors on ITMAconnect.

View More Articles